Technology - SK Process Monitor

Useful functions

Puzzlemaster

Puzzlemaster is an effective, yet easy to use tool to activate expert monitoring routines

for certain measuring tasks or processes.

Puzzlemaster is an effective, yet easy to use tool to activate expert monitoring routines

for certain measuring tasks or processes.

Just click on the desired puzzle symbol and all parameters will automatically adjust to the correct settings for different monitoring tasks such as:

- detection of rising slugs in stamping tools

- detection of rotated heads in cold forming

- detection of punch breakage

- detection of roll-backs on thread rollers

- activation of peak load monitoring

- activation of the Foxmatic monitoring technology

- selection of fast stop mode

- activation of profiled envelopes

- activation of zoom-channels

Partmaster

When you run a part and have found a good set-up for a well performing production, just memorize all monitoring parameters including the current force curves as reference for future runs by entering the part number.

When you run a part and have found a good set-up for a well performing production, just memorize all monitoring parameters including the current force curves as reference for future runs by entering the part number.

When the same part is produced again, just recall the memorized data and automatically set all monitoring parameters to the stored references.

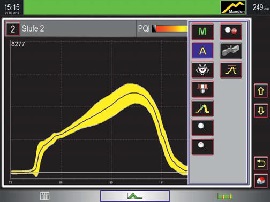

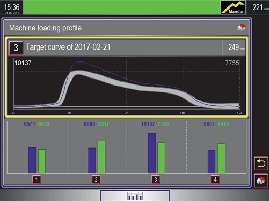

In addition, compare the current force curves with the memorized good target curves, both shown on the same screen of your monitor. You will see immediately any deviation and know in which direction tool and machine settings should be corrected to bring the current curve back in line with the memorized target curve.

Machinemaster

Gather and view relevant machine performance data such as stop/go diagram,

down times, down reasons, error types and error curves right at the process monitoring terminal.

Gather and view relevant machine performance data such as stop/go diagram,

down times, down reasons, error types and error curves right at the process monitoring terminal.

The stop/go diagram mirrors exactly the runtime behavior of the machine within the last 10 hours. In addition, you can page back into the log book as far as you want. The error log contains in chronological sequence all machine shut downs including stop reason, type and location of the error, and the related error force curve where applicable.

Thread rolling option

Schwer + kopka systems offer a variety of features designed specially

for the needs of thread rolling machines:

Schwer + kopka systems offer a variety of features designed specially

for the needs of thread rolling machines:

- DMI (Die Match Indicator) shows exactly if the rolling dies are perfectly matched, or else, in which direction and how much die match should be corrected

- roll-backs are detected and stop the machine immediately to prevent further damages

- Singlemaster detects the typical idle strokes and prevents the machine from stopping

- true rolling efficiency is recorded and displayed

Mandonmaster

Our unique Mandon®-system permanently “talks” to the machine operator. Mandon® is constantly thinking along with the process, gives timely warnings,

provides intelligent remedies, and offers precise recommendations on how to improve productivity and quality.

Our unique Mandon®-system permanently “talks” to the machine operator. Mandon® is constantly thinking along with the process, gives timely warnings,

provides intelligent remedies, and offers precise recommendations on how to improve productivity and quality.

For instance, if envelope limits are set far too wide, or if the current machine speed is below the prescribed target, or if a sensor is not working properly, and so forth.

Mandon® is your productivity insurance!