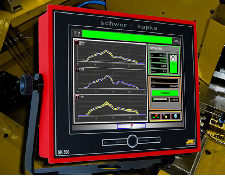

PRODUCT - SK process monitor

Main uses

Monitoring process force for the following metal working process and detecting process error.

- Cold forging

- Hot forming

- Thread rolling

- Metal sheet stamping

- Metal cutting and others

Monitoring process force continuously while machine cycle.

Preventing a defective part mixed into good parts by monitoring all parts in-process.

Main advantage

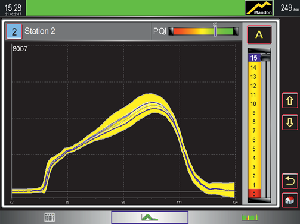

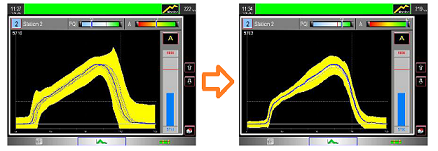

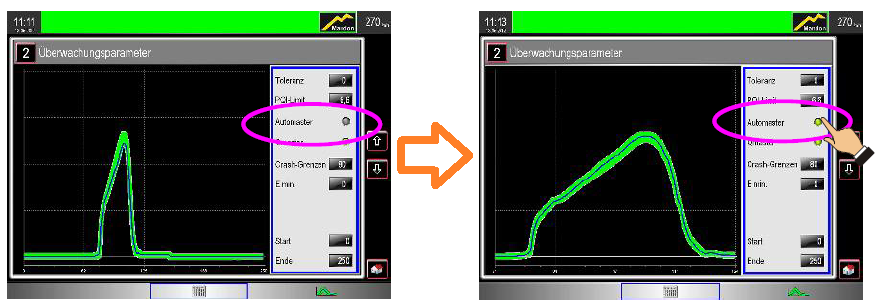

Auto envelope monitoring

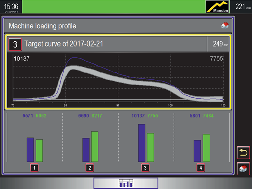

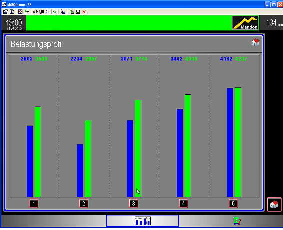

Trend monitoring (e.g. detecting tool wear)

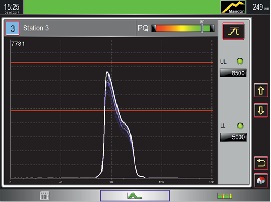

Possible to detect a small defect within envelope limit

And more and more..

Refer technical informationLine up

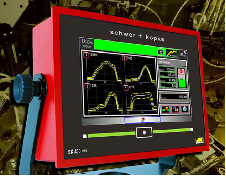

SK200

The smallest size

Use basic functions in a limited space

SK400

Small size

Many available options

SK500

Large screen

Many available options

SK800

The largest screen

Many available options

Main function table

Refer the following document also.

SK Process Monitor series Main functions description (pdf)| SK200 | SK400 | SK500 | SK800 | |

| Screen size | 4.3" | 7" | 10.4" | 15" |

| Input channel | 8 | 16 | 8 | 32 |

| Max.display channels at same time | 2 | 6 | 8 | 8 |

| Mandonic Auto Envelope | ✔ | ✔ | ✔ | ✔ |

| Peak monitoring | OP | OP | OP | OP |

| Trend monitoring | OP | ✔ | ✔ | ✔ |

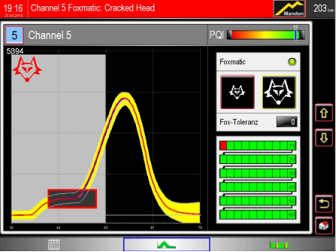

| Foxmatic technique | NA | OP | OP | OP |

| SKQmaster | OP | ✔ | ✔ | ✔ |

| PQI indicator | OP | ✔ | ✔ | ✔ |

| SKPartmaster | OP | OP | OP | OP |

| SKMachinemaster | NA | OP | OP | OP |

| SKPuzzlemaster | OP | OP | OP | OP |

| Mandon | NA | OP | OP | OP |

| SKProtectionmaster | NA | NA | OP | OP |

| DMI/DMA track monitor | NA | OP | OP | OP |

| SKAutomaster | OP | OP | OP | OP |

| Job/batch counter | OP | OP | OP | OP |

| Tool counter | NA | OP | OP | OP |

| SKPressmaster | OP | OP | OP | OP |