Technology - SK Process Monitor

Monitoring technic

Outline

When connected process machine is started production running, SK process monitor recognizes it and starts Leaning mode.

While Leaning mode, SK process monitor collects process force profiles for a while and sets envelope limit based

on the collected data considering normal fluctuation.

After that, SK process monitor is changed to Monitoring mode.

While Monitoring mode, SK process monitor is monitoring whether measured profile is within envelope limit. Envelope

limit is changing dynamically referring to actual force profiles.

High resolution envelope monitoring is today considered to be one of the most effective and reliable procedures to analyze and monitor production machinery, even at highest production speed.

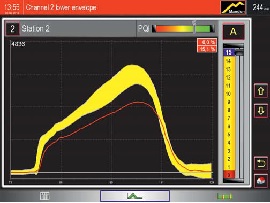

Envelope Monitoring

The monitoring system automatically puts a suitable envelope band with

upper and lower limits around the learnt force curve.

The monitoring system automatically puts a suitable envelope band with

upper and lower limits around the learnt force curve.

The Mandon Auto Envelope adjusts the width of the envelope perfectly to the variation of the force signal, tight envelope where the signal is stable, and wider where the signal is unstable.

This ensures that you always work with perfect fit limits.

The powerful signal processor is capable to monitor machines with even more than 2,000 cycles per minute. All SK process monitors are designed to compensate any variation in speed or RPM of the machine to avoid unnecessary machine stops.

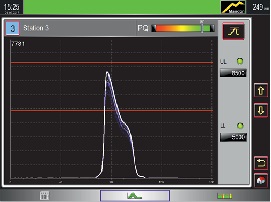

Detection envelope error

If the measured force signal does not fit into the learnt envelope, the machine will be stopped automatically to prevent further damage and more bad parts.

If the measured force signal does not fit into the learnt envelope, the machine will be stopped automatically to prevent further damage and more bad parts.

The monitor prompts an error message telling exactly where the error happened and what type of error was detected. This allows the operator to locate the problem easily and get the machine back into production quickly.

Peak Load Monitoring

By nature, some manufacturing processes show a high degree of variation in the measured signals.

By nature, some manufacturing processes show a high degree of variation in the measured signals.

Therefore applying the envelope technique may be too sensitive.

In this case, the respective channel can be switched over to Peak Load Monitoring.

The signal is compared against an adjustable upper and lower limit line. If a measured signal is higher than the upper limit, or does not reach the lower limit, the machine is stopped immediately.

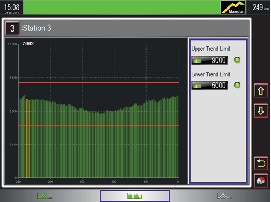

Trend Monitoring

Force signals can also gradually rise or fall over time without exceeding

any set limit. This effect is called trending.

Force signals can also gradually rise or fall over time without exceeding

any set limit. This effect is called trending.

S+K systems offer a Trend Monitoring option which prevents that the measured signals increase or decrease beyond acceptable limits. The limits are easily set and activated.

Detection of Trend Error

If forces exceed the upper trend limit or drop below the lower trend limit,

the machine is stopped immediately.

If forces exceed the upper trend limit or drop below the lower trend limit,

the machine is stopped immediately.

The reason for such a change in the force level can be tool or machine related. The monitor again gives an error message telling exactly where the error happened, and what trending error was detected.

Trend monitoring is an additional safety feature which prevents that the process moves too far away from the initial settings.

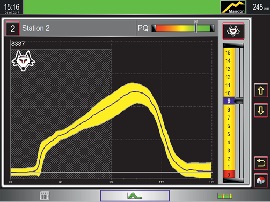

Foxmatic

Foxmatic is a unique monitoring algorithm working completely independent of the

set envelope bands.

Foxmatic is a unique monitoring algorithm working completely independent of the

set envelope bands.

Foxmatic uses the latest pattern recognition procedures to detect random faults such as cracked heads. It recognizes the fingerprint of the error and can tell the difference between true errors and normal process variation.

Foxmatic reacts to even the smallest changes in the force signals.

When a suspicious signal repeats itself over the next few ,cycles the machine will be stopped. Alternatively, a sorting signal can be generated to divert the defective or suspicious parts and keep the machine running.

SKQmaster

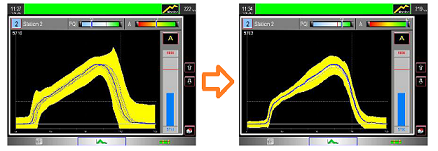

Some machines are fluctuating the cycle time for example chain or belt

drive machines.

Some machines are fluctuating the cycle time for example chain or belt

drive machines.

If the machine tact signal for process monitoring system is detected by

initiator, the monitoring system can't recognize the fluctuation while

the cycle.

Then each profiles are shifted and envelope limit is expanded.

As the result, the error detection ability of the monitoring system is decreased.

SK process monitor equips the solution.

SKQmaster is the function to compensate the tact signals.

SK process monitor keeps the correct envelope limit and accurate error detection.